Project Description

PET Bottle Washing Line

-Defining the amount of contamination in the applicable material.

-Defining the final usage of the finished product.

– How much capacity you need

Based on these specifications we would be in a position to engineer and manufacture a complete modular system for the application.

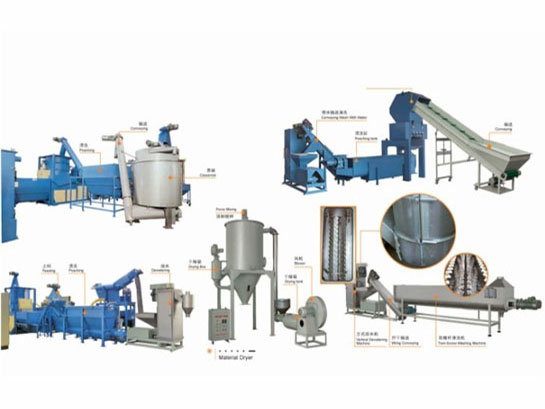

PET Bottle Recycle Line & PET bottle washing line maybe consist of:

also seePET Bottle Recycling process–Viedo Display

1. Bale breaker: For debale the baled PET bottles

2. Belt conveyor: Transport materials

3. Pre-washer: to separate foreign material such as glass, metal and stones.

4. Label remover: for separating the labels and other loose and foreign materials

5. Screw feeder: Transport materials as well as rub them for surface clean

6. Metal detector bridge: For detection of NE metal and protect the granulator and washing components

7. Separation table: For separate the foreign materials manually

8. Crusher: Crush the materials to flakes of 15mm (two series: one for PET, one for PP/PE)

9.Hot washer: clean the materials in hot water, sometimes with some chemicals

10. Poaching tank: For separation of the flakes with a specific density of <1g/cbm from >1g/cbm or in contrast to separate the flakes with a specific of > 1g/cbm form <1g/cbm ( PET >1g/cbm and PP/PE <1g/cbm )

11. Friction washer: Surface clean the materials ( two series: one for PET, one for PP/PE)

12. Dewatering machine:

for mechanical surface drying of the material flakes with rotating roller ( two series: one for PET, one for PP/PE)

Blowing and drying system:

1. For discharging and transporting the material from the dryer 2. For final drying of the material to the necessary residual level for down stream material processing

Cyclone silo:

1. for separation of dust and fine material to achieve a better quality final product

2.Storagefor the final products

As a professional waste plastic recyling machine manufacturer, Lianguan supplys a full range ofPP&PE film washing line,PVC pelletizing lines,PET bottle washing recycling lines.

Main Machine list

| Machine name | 300kg/h | 500kg/h | 1000kg/h | 1500kg/h | 2000kg/h | 3000kg/h |

| Baler Opener | 1set | 1set | 1set | 2sets | ||

| Belt Conveyor | 3sets | 3sets | 3sets | 3sets | 5sets | 7sets |

| Pre-Washer | 1set | 1set | 1set | 1set | ||

| Label Remover | 1set | 1set | 1set | 1set | 1set | 3sets |

| Sorting Table | 1set | 1set | 2sets | 2sets | ||

| Wet Crusher | 1set | 1set | 1set | 1set | 2sets | 3sets |

| Screw Loader | 3sets | 3sets | 3sets | 3sets | 6sets | 8sets |

| Hot Washer | 1set | 1set | 1set | 2set | 2sets | 3sets |

| Cold Washer | 1set | 1set | 1set | 1set | 2sets | 2sets |

| Friction Washer | 1set | 1set | 1set | 1set | 2sets | 3sets |

| Centrifugal Dewater | 1set | 1set | 1set | 1set | 2sets | 3sets |

| Drying Machine | 1set | 1set | 1set | 1set | ||

| Label Separator | 1set | 1set | 1set | 1set | 1set | 1set |

| Storage Hopper | 1set | 1set | 1set | 1set | 1set | 1set |

| Metal Detector | 1set | 1set | 1set | 1set | ||

| PLC Electric System | 1set | 1set | 1set | 1set | 1set | 1set |